Products

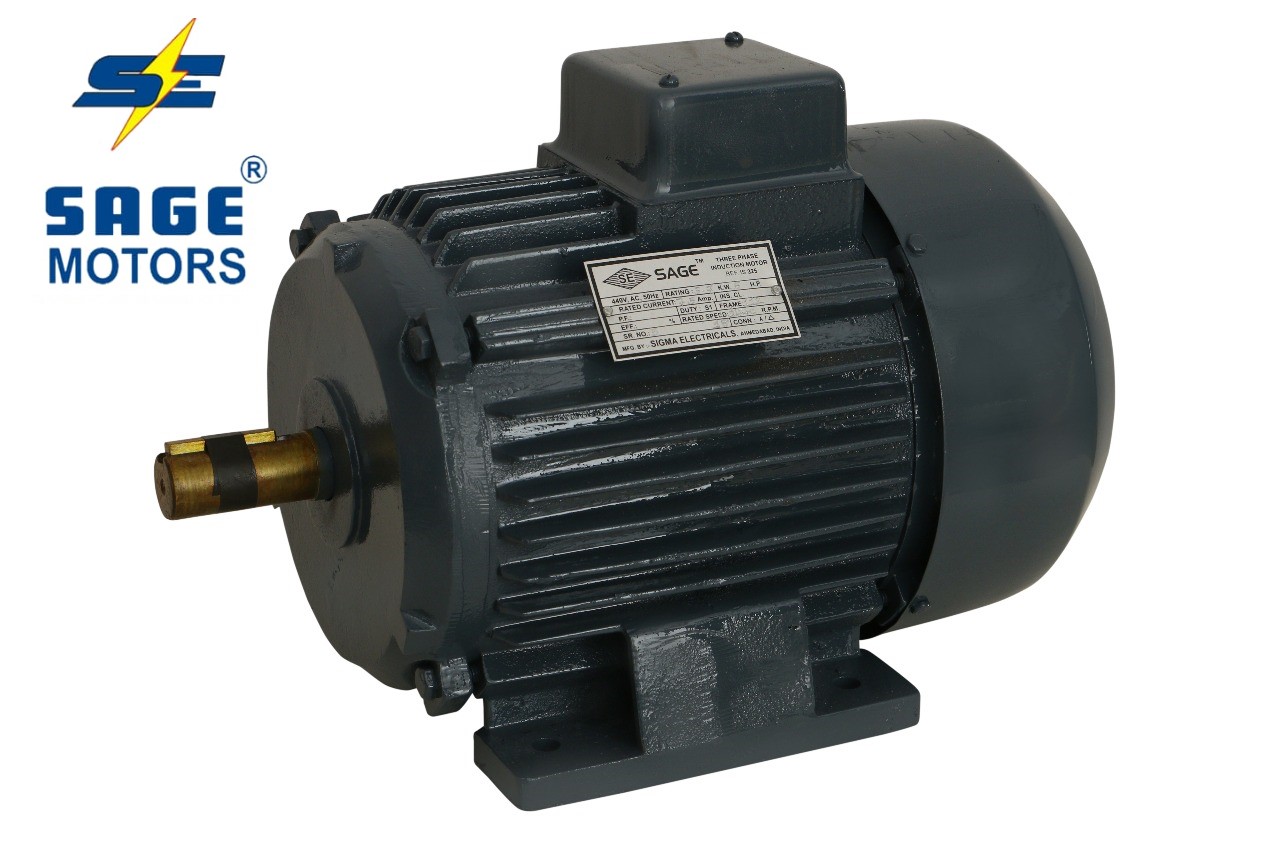

Induction Motor

Project Description

An induction Motor is a type of AC motor where power is supplied to the rotor by means of electromagnetic induction, rather than a commutator or slip rings as in other types of motor. These motors are widely used in industrial drives, particularly polyphase induction motors, because they are rugged and have no brushes. Single-phase versions are used in small appliances. Their speed is determined by the frequency of the supply current, so they are most widely used in constant-speed applications, although variable speed versions, using variable frequency drives are becoming more common. The most common type is the squirrel cage motor, and this term is sometimes used for induction motors generally.

Specifications

Single Phase Motor

Specifications

- MountingFace, Flange

- Single Phase0.37KW to 5 H.P. with Standard speed and various types of construction are available from frame size 90 to 132M.

- StandardsPerformance confirms to IS:996 Also Dimensions according to IS:1231 and IS:2223.

- FrameMotor are supplied in rugged cast iron frame integral feet. On request we can supply motor in aluminum body.

- RatingAll standard Single Phase Motors are continuous rated to comply with performance standards.

- Voltage and frequencyMotors are designed for Single Phase 230v ? 10% 50 HZ 5% Supply.

- Class Of InsulationAll standard motors are provided with class "B" insulation system. Motors with any other class of Insulation can be offered on request..

- RotorRotor are of high pressure aluminum die-cast. Its make motor low amplitudes of Vibration & Noise.

- LubricationBearing are adequately lubricated with lithium based high temp up to 150 deg. All the motors are supplied with C3 ball bearing & fully charged with lithium base grease at the time of assembly.

- Earthing TerminalMotor provided with minimum two earthing terminals. One in the terminal box and other on foot.

- Types Of ConstructionStandard motors with single shaft extension are for horizontal foot mounting (B3 as per IS 1231). Other types of construction available on request.

- Degree of ProtectionMotors have IP44 degree of protection as a standard feature conforming to IS 4691.

- NoiseMotors are designed for low noise level in accordance with IS 12065. Terminal Box :- Standard location of the terminal box is on the RHS viewed From Driving end Terminal Box can be rotated in the steps of 90 degree.

- Method Of startingAll the Motors Upto and including 2.2 Kw are connected in star internally and three terminals are brought out in the terminal box for D.O.L. Starting Motor Above 2.2 KW output are designed for continuous operation in Delta connection And Six terminals are brought out in the terminal box for star- delta starting .

- TestsAll Standard Motors can withstand momentary overload of 1.6 times of rated torque, for 15 seconda without stalling.

- Mechanical FeaturesSpecial Mountings, Shaft Extensions, Key way, Paint, Nameplate designs.

- PaintStandard Synthetic enamel (Bright Bule) paint is provided which is suitable for tropical conditions. However, special paint can be provided on request.

- Application

- Pumps

- Compressors

- Fans and blowers

- Flour Mills, Rolling Mills , Chaff Cutter

- Machine Tools

- Textile And Plastic Machineries

- Printing, packaging And Wood Working Machineries

- Material Handling Equipments

- Cranes, hoists

- Cooling Towers, etc.

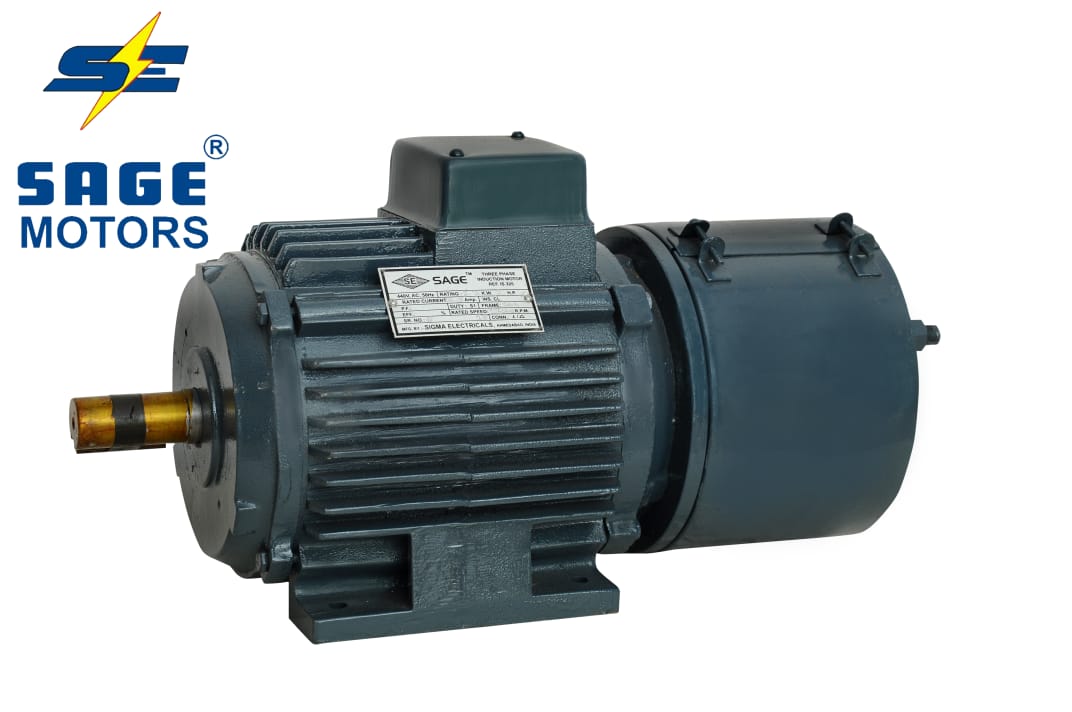

Three Phase Motor

Specifications

- Range :- Three PhaseMotor With Standard Rating And Duty cycles, Squirrel cage 0.37 KW to 22 KW With Standard Speed And Various types Of construction are available From frame size 71 to 180M.

- StandardsPerformance confirms to IS: 325. Also Dimensions according to IS:1231 and IS:2223.

- FrameMotor are supplied in rugged cast iron frame integral feet. On request we can supply motor in aluminum body.

- RatingAll standard Three Phase Motors are continuous rated to comply with performance standards.

- Voltage and frequencyMotors are designed for 415v? 10 % Three phase 50 Hz ? 5% supply.

- Class Of InsulationAll standard motors are provided with class "B" insulation system. Motors with any other class of Insulation can be offered on request..

- RotorRotor are of high pressure aluminum die-cast. Its make motor low amplitudes of Vibration & Noise.

- LubricationBearing are adequately lubricated with lithium based high temp up to 150 deg. All the motors are supplied with C3 ball bearing & fully charged with lithium base grease at the time of assembly.

- Earthing TerminalMotor provided with minimum two earthing terminals. One in the terminal box and other on foot.

- Types Of ConstructionStandard motors with single shaft extension are for horizontal foot mounting (B3 as per IS 1231). Other types of construction available on request.

- Degree of ProtectionMotors have IP44 degree of protection as a standard feature conforming to IS 4691.

- NoiseMotors are designed for low noise level in accordance with IS 12065. Terminal Box :- Standard location of the terminal box is on the RHS viewed From Driving end Terminal Box can be rotated in the steps of 90 degree.

- Method Of startingAll the Motors Upto and including 2.2 Kw are connected in star internally and three terminals are brought out in the terminal box for D.O.L. Starting Motor Above 2.2 KW output are designed for continuous operation in Delta connection And Six terminals are brought out in the terminal box for star- delta starting .

- TestsAll Standard Motors can withstand momentary overload of 1.6 times of rated torque, for 15 seconda without stalling.

- Mechanical FeaturesSpecial Mountings, Shaft Extensions, Key way, Paint, Nameplate designs.

- PaintStandard Synthetic enamel (Bright Bule) paint is provided which is suitable for tropical conditions. However, special paint can be provided on request.

- Application

- Pumps

- Compressors

- Fans and blowers

- Flour Mills, Rolling Mills , Chaff Cutter

- Machine Tools

- Textile And Plastic Machineries

- Printing, packaging And Wood Working Machineries

- Material Handling Equipments

- Cranes, hoists

- Cooling Towers, etc.

Face Motor

Specifications

- Range :- Three PhaseMotor With Standard Rating And Duty cycles, Squirrel cage 0.37 KW to 22 KW With Standard Speed And Various types Of construction are available From frame size 71 to 180M.

- StandardsPerformance confirms to IS: 325. Also Dimensions according to IS:1231 and IS:2223.

- FrameMotor are supplied in rugged cast iron frame integral feet. On request we can supply motor in aluminum body.

- RatingAll standard Three Phase Motors are continuous rated to comply with performance standards.

- Voltage and frequencyMotors are designed for 415v? 10 % Three phase 50 Hz ? 5% supply.

- Class Of InsulationAll standard motors are provided with class "B" insulation system. Motors with any other class of Insulation can be offered on request..

- RotorRotor are of high pressure aluminum die-cast. Its make motor low amplitudes of Vibration & Noise.

- LubricationBearing are adequately lubricated with lithium based high temp up to 150 deg. All the motors are supplied with C3 ball bearing & fully charged with lithium base grease at the time of assembly.

- Earthing TerminalMotor provided with minimum two earthing terminals. One in the terminal box and other on foot.

- Types Of ConstructionStandard motors with single shaft extension are for horizontal foot mounting (B3 as per IS 1231). Other types of construction available on request.

- Degree of ProtectionMotors have IP44 degree of protection as a standard feature conforming to IS 4691.

- NoiseMotors are designed for low noise level in accordance with IS 12065. Terminal Box :- Standard location of the terminal box is on the RHS viewed From Driving end Terminal Box can be rotated in the steps of 90 degree.

- Method Of startingAll the Motors Upto and including 2.2 Kw are connected in star internally and three terminals are brought out in the terminal box for D.O.L. Starting Motor Above 2.2 KW output are designed for continuous operation in Delta connection And Six terminals are brought out in the terminal box for star- delta starting .

- TestsAll Standard Motors can withstand momentary overload of 1.6 times of rated torque, for 15 seconda without stalling.

- Mechanical FeaturesSpecial Mountings, Shaft Extensions, Key way, Paint, Nameplate designs.

- PaintStandard Synthetic enamel (Bright Bule) paint is provided which is suitable for tropical conditions. However, special paint can be provided on request.

- Application

- Pumps

- Compressors

- Fans and blowers

- Flour Mills, Rolling Mills , Chaff Cutter

- Machine Tools

- Textile And Plastic Machineries

- Printing, packaging And Wood Working Machineries

- Material Handling Equipments

- Cranes, hoists

- Cooling Towers, etc.

Flange Motor

Specifications

Range :- Three PhaseMotor With Standard Rating And Duty cycles, Squirrel cage 0.37 KW to 22 KW With Standard Speed And Various types Of construction are available From frame size 71 to 180M.- StandardsPerformance confirms to IS: 325. Also Dimensions according to IS:1231 and IS:2223.

- FrameMotor are supplied in rugged cast iron frame integral feet. On request we can supply motor in aluminum body.

- RatingAll standard Three Phase Motors are continuous rated to comply with performance standards.

- Voltage and frequencyMotors are designed for 415v? 10 % Three phase 50 Hz ? 5% supply.

- Class Of InsulationAll standard motors are provided with class "B" insulation system. Motors with any other class of Insulation can be offered on request..

- RotorRotor are of high pressure aluminum die-cast. Its make motor low amplitudes of Vibration & Noise.

- LubricationBearing are adequately lubricated with lithium based high temp up to 150 deg. All the motors are supplied with C3 ball bearing & fully charged with lithium base grease at the time of assembly.

- Earthing TerminalMotor provided with minimum two earthing terminals. One in the terminal box and other on foot.

- Types Of ConstructionStandard motors with single shaft extension are for horizontal foot mounting (B3 as per IS 1231). Other types of construction available on request.

- Degree of ProtectionMotors have IP44 degree of protection as a standard feature conforming to IS 4691.

- NoiseMotors are designed for low noise level in accordance with IS 12065. Terminal Box :- Standard location of the terminal box is on the RHS viewed From Driving end Terminal Box can be rotated in the steps of 90 degree.

- Method Of startingAll the Motors Upto and including 2.2 Kw are connected in star internally and three terminals are brought out in the terminal box for D.O.L. Starting Motor Above 2.2 KW output are designed for continuous operation in Delta connection And Six terminals are brought out in the terminal box for star- delta starting .

- TestsAll Standard Motors can withstand momentary overload of 1.6 times of rated torque, for 15 seconda without stalling.

- Mechanical FeaturesSpecial Mountings, Shaft Extensions, Key way, Paint, Nameplate designs.

- PaintStandard Synthetic enamel (Bright Bule) paint is provided which is suitable for tropical conditions. However, special paint can be provided on request.

- Application

- Pumps

- Compressors

- Fans and blowers

- Flour Mills, Rolling Mills , Chaff Cutter

- Machine Tools

- Textile And Plastic Machineries

- Printing, packaging And Wood Working Machineries

- Material Handling Equipments

- Cranes, hoists

- Cooling Towers, etc.

Vibrator Motor

Specifications

Range0.25 HP to 10 HP in 2, 4, 6 & 8 poles 3 phase supply volts 415 ? 5% 50 Hz.? 5%- DesignThe external vibrator is a three phase synchronous motor which has eccentric weights (unbalanced weight0 mounted at the ends of the Rotor shaft. the rotating shaft causes centrifugal forced which can be adjusted by moving the weight it created a vibration.

- Protection SystemMotors are completely sealed and meet the requirements of safety class IP-65.

- Centrifugal force settingCentrifugal forces can be regulated with the easily adjustable eccentric weights with graduations to suit practical applications.

- ApplicationsMotor is designed for Creating vibration. Motor use in Pharmaceuticals, construction, Chemical Industries, ceramic Industries for different.

Break Motor

Specifications

- Brake Motor are for various applications Requiring almost instant stopping of drive lord.

- The motor brake in case of power supply failure ensuring further to a precise stop and quick bracking action, the security of sudden inter venation in case of an unintentional power supply failure (i.e. power supply black-out. equipment failure.) This brake call fail safe brake.

- The braking action is obtained without axial sliding of shaft and provided equal braking torque in both directions of rotations.

- Basically brake motor combination of an a.c. induction motor and a disc type, fail safe Electromagnetic brake unit. Brake motor are mfg. as per application motor available in foot, Flange & Face Mounting.

- Brake Motor are specially suitable to be used with lifting Machineries, Textile Machinery, Geared motor, Cable Reeling Drums, Rolling Mills, Machine tools.

- We can also supply electromagnetic single face brake on customer request (this brake is not failsafe). for textile application. This brake is operation by power supply D.C.

- Rotor is positive locking with shaft key joint so that can not move on high full lord torque.

- 0.25 h.p. to 30 h.p. in 3000, 1500, 1000 & 750 RPM with A.C. and D.C. brake frame 71 to 180 L.

- Insulation class B & F (H. class also supplied on customer Request.)

Special Motors

Project Description

1.Extend Shaft 6.Gear Shaft

2.Threaded Shaft 7.Hollow Shaft Motor

3.Special Mounting 8.Aluminum Body

4.Special Material shaft 9.H Class Motor

5.Light Weight Motor

Electric Needle Vibrator

Product Description

We have marked a niche for ourselves as one of the foremost manufacturers of Needle Vibrators. We have with us varied models of vibrators and amongst them; Electric Needle Vibrator has gained immense recognition in the construction industry for its high proficiency and accurate results.

In terms of construction, these needle vibrators are one step ahead of other brands as these are presented in industry with high grade construction and heavy duty components. The prime use of the needle vibrator is mixing of concrete with checking that any bubble will not left in the mixture. All the equipments before supplying at the client's end is stringently tested on various quality parameters.

Specifications

Technical Specification

- Prime mover:2 or 3 HP & 1 or 3 Phase, 2800 RMP Electric Motor.

- Accessories:Revolving base Frame Stand & Needle Fitting Attachments.

- Suitable Needles:25/30/40/60 mm Needle with 6 mtr. Long flexible Shaft

- Advantages:

- Low power consumption

- Easy to operate

- Precise results

- Proper Mixing of concrete

- High operational fluency

- High strength

- Strong Construction

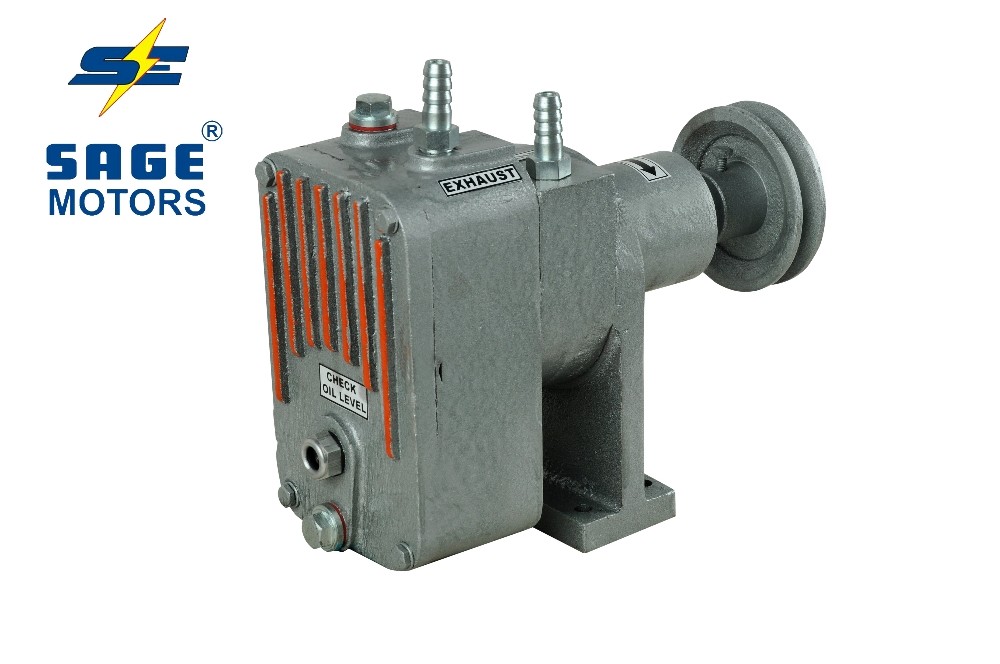

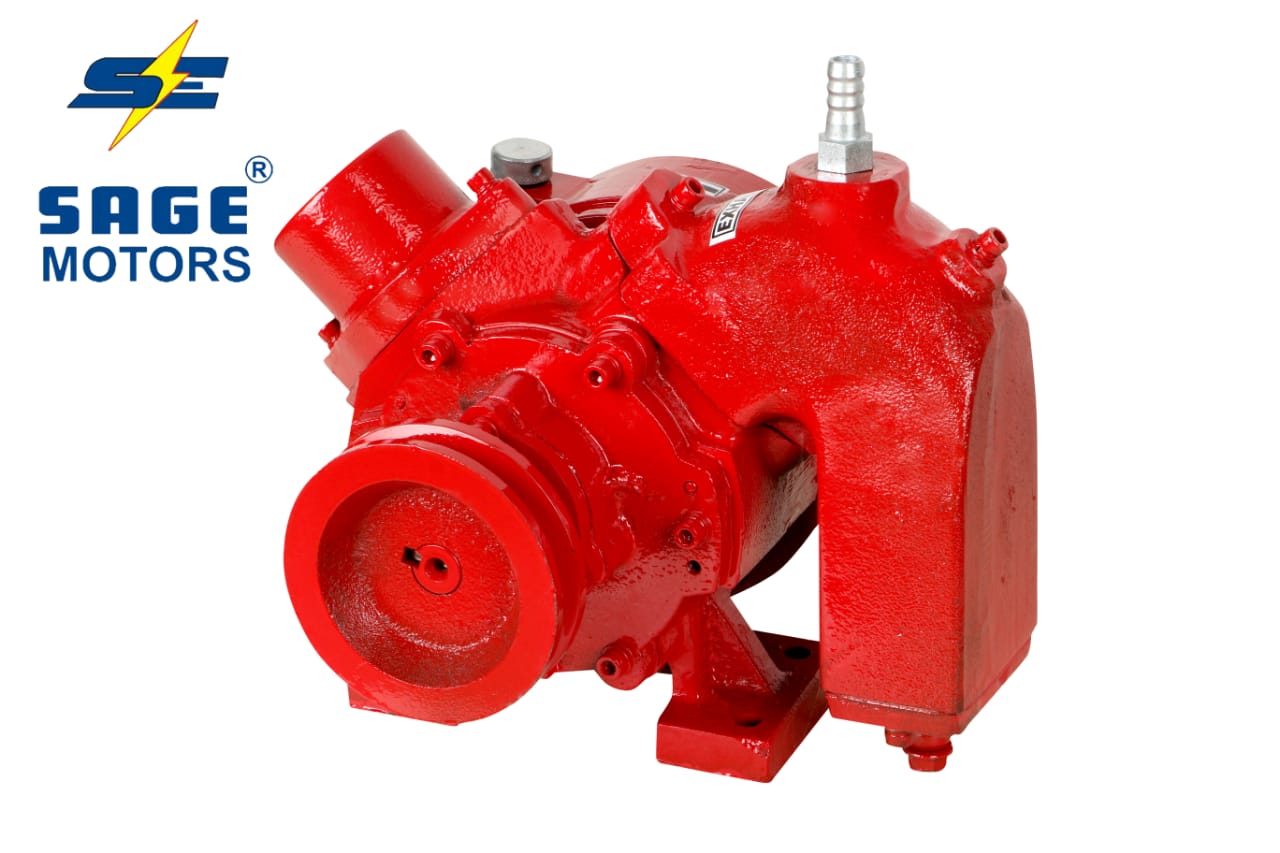

SG 120

Specifications

1). LPM

– 120 (OIL LIBRICTED)

2). HP

-0.5 (1440 RPM) SINGLE PHASE & THREE PHASE

3). SINGLE

BUCKET

4). MAX

DISTANCE 120FT

5). TEMP

:- 120°C (1 HRS)

6). VACCUM

PORT – 3/8 BSP THREADING

300 LPM

Specifications

1). LPM

– 300 LPM (OIL LIBRICTED)

2). HP –

1 HP(1440 RPM) SINGLE PHASE & THREE PHASE

3).

DOUBLE BUCKET

4). MAX

DISTANCE 200FT (DOUBLE BUCKET)

5). TEMP

:- 125°C (1 HRS)

6). VACCUM

PORT – 3/8 BSP THREADING

7).

FILTER AVAILABLE

120 LPM MONO

Specifications

1). LPM

– 120 0.5 HP MONO (OIL LIBRICTED)

2). HP

-0.5 (2800 RPM) SINGLE PHASE & THREE PHASE

3). SINGLE

BUCKET

4). MAX

DISTANCE 80FT

5). TEMP

:- 120°C (1 HRS)

6). VACCUM

PORT – 1/2 BSP THREADING

7).

FILTER AVAILABLE

400 LPM

Specifications

1). LPM

– 400 LPM (OIL LIBRICTED)

2). HP –

1 HP(1440 RPM) SINGLE PHASE & THREE PHASE

3).

DOUBLE BUCKET

4). MAX

DISTANCE 150FT (TRIPLE BUCKET)

200FT

(DOUBLE BUCKET)

5). TEMP

:- 125°C (1 HRS)

6). VACCUM

PORT – 3/8 BSP THREADING

7).

FILTER AVAILABLE